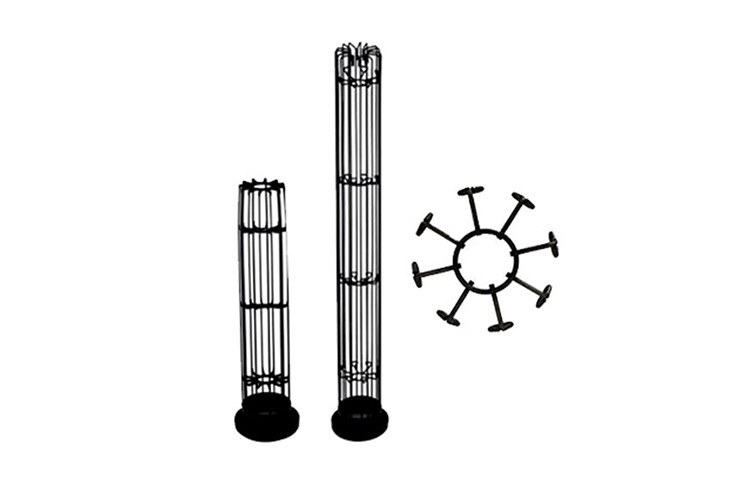

Galvanized filter cage for baghouse

Release time:

2025-06-13

Galvanized filter cage for baghouse is a key component in bag filter and plays an indispensable role in industrial dust control.

Galvanized filter cage for baghouse is a key component in bag filter and plays an indispensable role in industrial dust control.

1. Material and process

Galvanized material

The filter cage is made of galvanized material. The galvanizing treatment provides the filter cage with good corrosion resistance, enabling it to adapt to various complex working environments. Whether in a high humidity environment or in an industrial scene containing corrosive gases, such as the chemical, printing and dyeing industries, the galvanized layer can effectively prevent the filter cage from rusting and corroding, greatly extending the service life of the filter cage.

Manufacturing process

In terms of manufacturing process, the filter cage is precisely processed and welded. The welding parts are firm to ensure the stability of the overall structure of the filter cage. Its manufacturing process strictly follows relevant standards to ensure the dimensional accuracy of the filter cage. This allows the filter cage to perfectly match the filter bag to avoid gaps that are too large or too small. A gap that is too large may cause dust leakage, and a gap that is too small may affect the normal installation and removal of the filter bag.

2. Structural features

Support performance

The structural design of the galvanized filter cage for baghouse is to provide good support for the filter bag. It has a reasonable spacing and shape, which can evenly disperse the pressure on the filter bag. When the dust-laden gas enters the bag filter, the filter bag maintains its shape under the support of the filter cage, ensuring that the gas can pass through the filter bag evenly and improve the filtration efficiency.

Strength and durability

It has high strength and can withstand certain impact and vibration. During the operation of the dust collector, such as the impact force generated by pulse jet cleaning, the filter cage will not be easily deformed or damaged. This strength and durability ensures that the filter cage can always work normally during long-term use, reducing the frequency of equipment maintenance and replacement of filter cages and reducing operating costs.

3. Application scope

Galvanized filter cage for baghouse is widely used in many industrial fields, including power, steel, building materials and other industries. In the boiler flue gas dust removal in the power industry, it can effectively filter fly ash, reduce dust emissions and protect the environment. In the sintering and ironmaking processes of the steel industry, it can capture a large amount of dust generated during the production process, improve the working environment of the workshop, and recover valuable dust resources. In the building materials industry, such as cement plants and brick and tile plants, it is also an important equipment component for controlling dust emissions.

latest News