Understanding 2400mm Length Filter Bags: Essential Insights for Effective Filtration

Release time:

2025-06-13

Filter bags play a pivotal role in industrial filtration processes, ensuring that contaminants are effectively captured and removed from air or liquid streams. Among the various specifications available, the 2400mm length filter bag stands out, particularly for its unique dimensions and versatility. This article aims to provide comprehensive insights into the importance of 2400mm length filter bag

Filter bags play a pivotal role in industrial filtration processes, ensuring that contaminants are effectively captured and removed from air or liquid streams. Among the various specifications available, the 2400mm length filter bag stands out, particularly for its unique dimensions and versatility. This article aims to provide comprehensive insights into the importance of 2400mm length filter bags, focusing on their applications, benefits, and material considerations.

One of the primary benefits of using 2400mm length filter bags is their ability to accommodate larger filtering systems. These bags are typically used in applications where significant volumes of air or liquid need to be processed, such as in dust collection systems or wastewater treatment facilities. The extended length allows for a larger surface area, which enhances the filtration capacity and efficiency, leading to better performance in capturing particulates and contaminants.

In terms of material, 2400mm length filter bags can be made from a variety of fabrics, including polyester, polypropylene, and nylon. Each material offers distinct advantages based on the specific application. For instance, polyester filter bags are often used in environments with moderate temperatures and humidity, while polypropylene is preferred for its chemical resistance, making it suitable for harsher industrial processes. Understanding the properties of these materials helps in selecting the right filter bag that aligns with operational requirements.

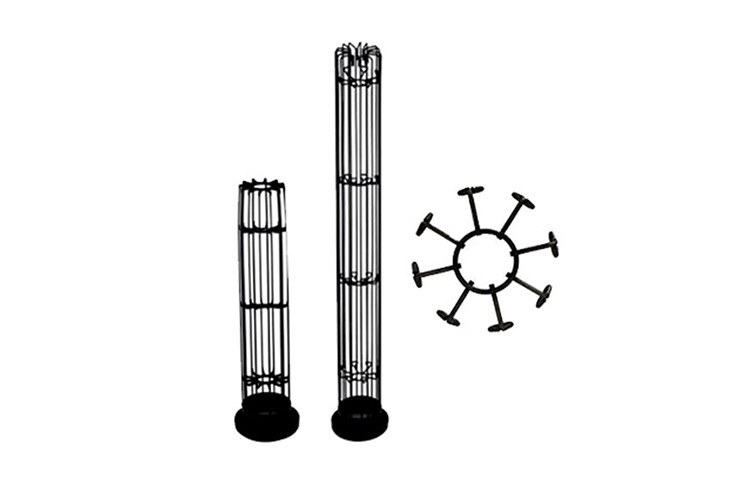

Moreover, the design and construction of 2400mm length filter bags are crucial. Key features such as seam types, bag shape (such as cylindrical or flat), and the presence of support cages can significantly influence their performance. Properly designed filter bags ensure optimal airflow, reduce the risk of blinding, and facilitate easier maintenance.

Another important consideration is the filtration efficiency of the 2400mm length filter bag. Filtration efficiency is often measured by the bag’s ability to capture specific particle sizes. A higher efficiency rating indicates that the bag can effectively trap smaller particles, which is essential in industries where air quality or liquid purity is critical.

Additionally, regular maintenance and timely replacement of filter bags are vital to sustaining their performance. Over time, filter bags may become clogged, reducing their efficiency and potentially causing system failures. Therefore, monitoring the condition of filter bags and adhering to maintenance schedules is crucial for ensuring that industrial filtration systems operate smoothly.

In conclusion, 2400mm length filter bags are an integral component of many industrial filtration systems. Their unique dimensions, material options, and design features make them highly effective for various applications. By understanding the role of these filter bags, industries can enhance their filtration processes, ensuring cleaner air and liquids, while also improving operational efficiency.

One of the primary benefits of using 2400mm length filter bags is their ability to accommodate larger filtering systems. These bags are typically used in applications where significant volumes of air or liquid need to be processed, such as in dust collection systems or wastewater treatment facilities. The extended length allows for a larger surface area, which enhances the filtration capacity and efficiency, leading to better performance in capturing particulates and contaminants.

In terms of material, 2400mm length filter bags can be made from a variety of fabrics, including polyester, polypropylene, and nylon. Each material offers distinct advantages based on the specific application. For instance, polyester filter bags are often used in environments with moderate temperatures and humidity, while polypropylene is preferred for its chemical resistance, making it suitable for harsher industrial processes. Understanding the properties of these materials helps in selecting the right filter bag that aligns with operational requirements.

Moreover, the design and construction of 2400mm length filter bags are crucial. Key features such as seam types, bag shape (such as cylindrical or flat), and the presence of support cages can significantly influence their performance. Properly designed filter bags ensure optimal airflow, reduce the risk of blinding, and facilitate easier maintenance.

Another important consideration is the filtration efficiency of the 2400mm length filter bag. Filtration efficiency is often measured by the bag’s ability to capture specific particle sizes. A higher efficiency rating indicates that the bag can effectively trap smaller particles, which is essential in industries where air quality or liquid purity is critical.

Additionally, regular maintenance and timely replacement of filter bags are vital to sustaining their performance. Over time, filter bags may become clogged, reducing their efficiency and potentially causing system failures. Therefore, monitoring the condition of filter bags and adhering to maintenance schedules is crucial for ensuring that industrial filtration systems operate smoothly.

In conclusion, 2400mm length filter bags are an integral component of many industrial filtration systems. Their unique dimensions, material options, and design features make them highly effective for various applications. By understanding the role of these filter bags, industries can enhance their filtration processes, ensuring cleaner air and liquids, while also improving operational efficiency.

latest News