How to Judge the Quality of a 2000mm Low Pressure Drop Filter Bag

Release time:

2025-12-03

In industrial dust removal systems, 2000mm low pressure drop filter bags are widely used due to their low operating resistance and high filtration efficiency.

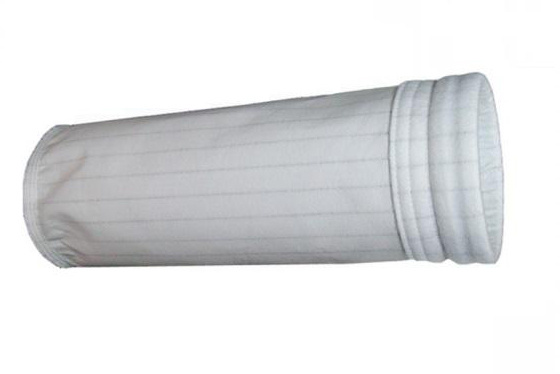

In industrial dust removal systems, 2000mm low pressure drop filter bags are widely used due to their low operating resistance and high filtration efficiency. However, the quality of filter bags on the market varies greatly, making it crucial to determine their quality during procurement and use. Judging the quality of a 2000mm low pressure drop filter bag involves a comprehensive evaluation from multiple dimensions, including materials, structural manufacturing processes, filtration performance, durability, and usage performance.

First, the filter bag material is the fundamental factor determining performance. High-quality low pressure drop filter bags typically use filter materials with uniform fiber fineness and good temperature and chemical resistance, such as polyester, aramid, and PTFE membrane. The smoothness of the material surface and the uniformity of fiber distribution are direct indicators of quality. Furthermore, if the product uses membrane technology, it can further improve filtration accuracy and reduce initial resistance; therefore, the integrity of the membrane layer and the absence of damage or unevenness should be checked.

Second, the manufacturing process directly affects the stability and service life of the filter bag. High-quality filter bags should have neat, firm stitches with uniform stitch density. The fastening structure at the bag opening should be tight, without skipped stitches, broken threads, or loose seams. For 2000mm long filter bags, special attention should be paid to whether the longitudinal dimensions are standard and whether the bag body is sturdy to avoid deformation and wrinkling during operation after installation, which would increase resistance.

Third, filtration performance and pressure drop are core evaluation indicators. High-quality filter bags have low initial pressure drop and a stable increase in resistance during operation, without sudden increases in pressure drop within a short period. When purchasing, refer to the test data provided by the manufacturer, such as air permeability, filtration speed, and initial resistance, or observe its operating effect through on-site testing.

Furthermore, durability is an important criterion for judging the quality of filter bags. A high-quality 2000mm low pressure drop filter bag should have good resistance to abrasion, acids and alkalis, and hydrolysis, and maintain structural stability under high-frequency pulse backflushing conditions. It should not easily fuzz or shed powder, nor should it age rapidly due to fluctuations in humidity and temperature.

Actual user feedback is also a very crucial reference factor. If the filter bag exhibits stable and compliant emissions, slow pressure loss growth, good dust removal performance, and a long service life during long-term operation, its reliability can be proven.

When selecting a 2000mm low pressure drop filter bag, its materials, manufacturing process, performance, and usage should be comprehensively considered to assess its quality from multiple dimensions, ensuring the efficient and stable operation of the dust collection system.

latest News