Understanding PPS PTFE Composite Filter Bags: A Comprehensive Guide

Release time:

2025-06-03

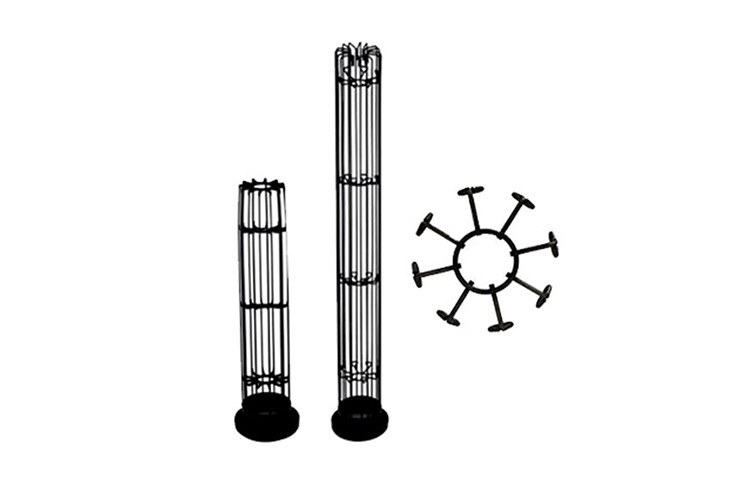

PPS PTFE composite filter bags are advanced filtration solutions designed to meet the rigorous demands of various industrial applications. Constructed from polyphenylene sulfide (PPS) and polytetrafluoroethylene (PTFE), these filter bags leverage the unique properties of both materials to provide exceptional filtration performance and durability. One of the standout features of PPS is its high res

PPS PTFE composite filter bags are advanced filtration solutions designed to meet the rigorous demands of various industrial applications. Constructed from polyphenylene sulfide (PPS) and polytetrafluoroethylene (PTFE), these filter bags leverage the unique properties of both materials to provide exceptional filtration performance and durability.

One of the standout features of PPS is its high resistance to heat and chemical degradation. This makes it ideal for use in environments that experience extreme temperatures or aggressive chemical exposure. When combined with PTFE, which is renowned for its non-stick properties and excellent chemical resistance, the resulting composite filter bag achieves a remarkable level of performance. This combination allows for effective filtration of a wide range of particulates, including fine dust and aggressive particles.

The applications of PPS PTFE composite filter bags are extensive. They are commonly utilized in industries such as pharmaceuticals, food processing, and chemical manufacturing, where cleanliness and efficiency are paramount. These filter bags excel in environments where traditional materials may fail, offering longer service life and reduced maintenance needs. By effectively capturing contaminants, they help maintain product purity and compliance with health and safety standards.

Another significant advantage of PPS PTFE composite filter bags is their ability to operate under varying conditions without sacrificing performance. Their temperature tolerance often exceeds 200 degrees Celsius, making them suitable for high-temperature applications. Furthermore, the hydrophobic nature of PTFE ensures that moisture does not compromise the filtration process, which is particularly beneficial in humid environments.

In addition to their functional benefits, these filter bags are designed with user convenience in mind. They can be easily integrated into existing filtration systems, and their lightweight nature simplifies installation and replacement. This not only saves time but also reduces the overall operational costs associated with filtration maintenance.

In summary, PPS PTFE composite filter bags represent a significant advancement in filtration technology. Their unique properties allow them to outperform traditional filter materials in challenging environments, making them an ideal choice for a variety of industrial applications. By investing in these composite filter bags, industries can enhance their filtration efficiency, reduce downtime, and ensure compliance with stringent regulatory requirements. Whether you are in the pharmaceutical, food processing, or chemical sectors, understanding and utilizing PPS PTFE composite filter bags can lead to improved process reliability and product quality.

One of the standout features of PPS is its high resistance to heat and chemical degradation. This makes it ideal for use in environments that experience extreme temperatures or aggressive chemical exposure. When combined with PTFE, which is renowned for its non-stick properties and excellent chemical resistance, the resulting composite filter bag achieves a remarkable level of performance. This combination allows for effective filtration of a wide range of particulates, including fine dust and aggressive particles.

The applications of PPS PTFE composite filter bags are extensive. They are commonly utilized in industries such as pharmaceuticals, food processing, and chemical manufacturing, where cleanliness and efficiency are paramount. These filter bags excel in environments where traditional materials may fail, offering longer service life and reduced maintenance needs. By effectively capturing contaminants, they help maintain product purity and compliance with health and safety standards.

Another significant advantage of PPS PTFE composite filter bags is their ability to operate under varying conditions without sacrificing performance. Their temperature tolerance often exceeds 200 degrees Celsius, making them suitable for high-temperature applications. Furthermore, the hydrophobic nature of PTFE ensures that moisture does not compromise the filtration process, which is particularly beneficial in humid environments.

In addition to their functional benefits, these filter bags are designed with user convenience in mind. They can be easily integrated into existing filtration systems, and their lightweight nature simplifies installation and replacement. This not only saves time but also reduces the overall operational costs associated with filtration maintenance.

In summary, PPS PTFE composite filter bags represent a significant advancement in filtration technology. Their unique properties allow them to outperform traditional filter materials in challenging environments, making them an ideal choice for a variety of industrial applications. By investing in these composite filter bags, industries can enhance their filtration efficiency, reduce downtime, and ensure compliance with stringent regulatory requirements. Whether you are in the pharmaceutical, food processing, or chemical sectors, understanding and utilizing PPS PTFE composite filter bags can lead to improved process reliability and product quality.

latest News