Enhancing Air Quality: The Vital Role of Dust Collector Filter Bags

Release time:

2025-04-06

Enhancing Air Quality: The Vital Role of Dust Collector Filter Bags Table of Contents 1. Introduction to Dust Collector Filter Bags 2. Understanding Air Quality in Industrial Settings 3. Importance of Dust Collection Systems 4. Types of Dust Collector Filter Bags 4.1 Felt Filter Bags 4.2 Woven Filter Bags 4.3 Pleated Filter Bags

Enhancing Air Quality: The Vital Role of Dust Collector Filter Bags

Table of Contents

- 1. Introduction to Dust Collector Filter Bags

- 2. Understanding Air Quality in Industrial Settings

- 3. Importance of Dust Collection Systems

- 4. Types of Dust Collector Filter Bags

- 5. Applications of Dust Collector Filter Bags

- 6. Maintenance Best Practices for Filter Bags

- 7. Common Issues and Solutions

- 8. Future Trends in Dust Collection Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Dust Collector Filter Bags

In today's industrial landscape, maintaining high air quality is not just a regulatory requirement but also a moral imperative. **Dust collector filter bags** play a crucial role in this effort, acting as the frontline defense against airborne particulates in various industrial environments. By filtering out dust particles and other contaminants, these filter bags contribute significantly to creating a safer and healthier workspace for employees.

2. Understanding Air Quality in Industrial Settings

Air quality in industrial settings is often compromised due to the presence of harmful particles, gases, and other emissions. Dust, smoke, and chemical vapors can lead to various health issues for employees, including respiratory problems and long-term diseases. Understanding the sources of these pollutants is essential for implementing effective filtration solutions.

2.1 The Impact of Poor Air Quality

Poor air quality can have serious implications, not only for health but also for productivity and equipment longevity. High levels of dust and particulate matter can lead to increased absenteeism and decreased performance. Moreover, machinery exposed to dust can suffer from wear and tear, leading to costly repairs and downtime.

3. Importance of Dust Collection Systems

Effective dust collection systems are integral to managing air quality in industrial settings. These systems work by capturing dust and particles before they can circulate throughout the workspace. They consist of ducting, fans, and dust collector filter bags that work together to ensure efficient air purification.

3.1 Regulatory Compliance

Many industries must adhere to strict regulations regarding air emissions and air quality standards. Using dust collector filter bags helps companies comply with these regulations, avoiding costly fines and legal repercussions.

3.2 Worker Health and Safety

Maintaining clean air in the workplace is essential for the health and safety of employees. **Dust collector filter bags** mitigate the risks associated with airborne contaminants, contributing to a healthier workforce and reducing health-related costs for employers.

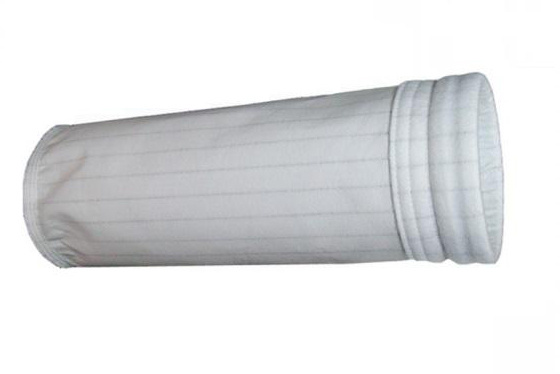

4. Types of Dust Collector Filter Bags

Selecting the right type of dust collector filter bag is crucial for ensuring optimal performance in dust collection systems. Various materials and designs suit different applications, and understanding these options can enhance air quality management.

4.1 Felt Filter Bags

Felt filter bags are commonly used in industrial applications due to their excellent filtration capabilities. Made from synthetic or natural fibers, they effectively capture fine particles. Their ability to tolerate high temperatures makes them suitable for industries like metalworking and food processing.

4.2 Woven Filter Bags

Woven filter bags are designed for durability and are often used in applications with harsher conditions. These bags are made from tightly woven materials that offer excellent resistance to wear and tear. They are ideal for industries that generate large volumes of dust, such as woodworking and cement manufacturing.

4.3 Pleated Filter Bags

Pleated filter bags offer increased surface area compared to traditional flat bags, allowing for greater dust collection efficiency. Their compact design enables them to fit in smaller spaces while providing superior airflow and filtration capabilities. This makes them a popular choice in various industrial applications.

5. Applications of Dust Collector Filter Bags

Dust collector filter bags find applications across a range of industries, each with unique dust management needs.

5.1 Manufacturing

In manufacturing environments, dust generated from machines, cutting tools, and processes necessitates effective filtration to ensure a clean workspace.

5.2 Pharmaceuticals

The pharmaceutical industry requires stringent air quality control to prevent contamination. Dust collector filter bags are vital for maintaining cleanroom standards.

5.3 Food Processing

In food processing, maintaining product integrity and hygiene is paramount. Dust collector filter bags help in achieving this by removing particulates that could compromise product quality.

5.4 Woodworking

Woodworking generates significant amounts of sawdust and wood shavings. Dust collector filter bags are essential for managing this debris and ensuring a safe working environment.

6. Maintenance Best Practices for Filter Bags

To ensure that dust collector filter bags operate at peak efficiency, regular maintenance is crucial.

6.1 Regular Inspections

Conducting regular inspections can help identify issues such as tears, clogs, or wear that could compromise filtration efficiency.

6.2 Cleaning and Replacement

Cleaning methods vary based on the type of filter bag used. Some bags may be cleaned and reused, while others will require periodic replacement to maintain air quality standards.

6.3 Monitoring Airflow

Monitoring airflow and pressure drop across filter bags can provide insights into their performance. A sudden drop in airflow could indicate that the bags need cleaning or replacement.

7. Common Issues and Solutions

While dust collector filter bags are effective in enhancing air quality, certain issues can arise. Understanding how to address these problems can ensure optimal operation.

7.1 Clogging

Clogged filter bags can lead to decreased airflow and filtration efficiency. Regular cleaning can mitigate this issue, but if clogging persists, more frequent replacement may be necessary.

7.2 Wear and Tear

Over time, filter bags can experience wear and tear. Using high-quality bags designed for specific applications can reduce the risk of damage.

7.3 Inadequate Filtration

In some cases, the filter bag may not provide adequate filtration for certain types of dust or particles. Assessing the type of particles generated in the facility can guide the selection of appropriate filter bags.

8. Future Trends in Dust Collection Technology

As industries evolve, so too do dust collection technologies. Emerging trends include advancements in smart filtration systems that utilize IoT (Internet of Things) for monitoring and maintenance. This technology allows for real-time data analysis to optimize filter bag performance and enhance air quality management.

9. Frequently Asked Questions

9.1 What are dust collector filter bags made of?

Dust collector filter bags can be made from various materials, including felt, woven fabric, and synthetic fibers, each chosen based on the specific application.

9.2 How often should filter bags be replaced?

The replacement frequency depends on usage, type of dust, and operational conditions. Regular inspections can help determine when replacements are needed.

9.3 Can filter bags be cleaned and reused?

Many filter bags can be cleaned and reused; however, some types may need to be replaced after a certain period or level of contamination.

9.4 How do I know if my filter bags are performing well?

Monitoring airflow and pressure drop across the filter bags, along with regular inspections, can provide insights into their performance.

9.5 What are the health benefits of using dust collector filter bags?

Using dust collector filter bags improves air quality, reduces health risks for employees, and ensures compliance with environmental regulations.

10. Conclusion

Dust collector filter bags are an essential component of effective air quality management in industrial settings. By understanding their types, applications, and maintenance practices, companies can significantly enhance workplace safety and compliance with regulations. Investing in quality filter bags not only protects employee health but also contributes to operational efficiency. As technology continues to advance, the integration of smart systems will further optimize dust collection processes, ensuring cleaner air and a healthier work environment for all.

latest News