High-Efficiency Filtration Solutions—Advantages and Applications of Polyester Needle Felt Filter Bags

Release time:

2025-08-13

Polyester needle felt filter bags, with their excellent performance and wide applicability, have become the preferred filter material for many companies

In industrial dust control and air purification, the choice of filter bag directly impacts the efficiency and lifespan of dust removal equipment. Polyester needle felt filter bags, with their excellent performance and wide applicability, have become the preferred filter material for many companies.

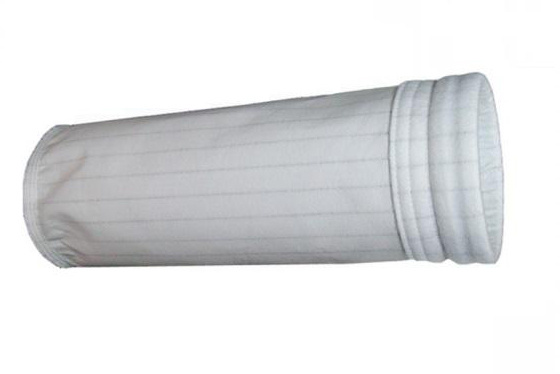

Polyester needle felt filter bags are made from high-quality polyester fibers, needle-punched into a non-woven fabric. They are then processed through heat setting, singeing, calendering, or lamination to create finished filter bags. This structure not only ensures the stability of the filter media but also provides excellent surface flatness, effectively preventing dust infiltration and clogging.

In terms of performance, polyester needle felt filter bags offer the following significant advantages:

Moderate temperature resistance: They can operate stably at temperatures around 130°C for extended periods and withstand temperatures of 150°C for short periods.

High filtration efficiency: The three-dimensional interlaced fiber structure provides a high dust capture capacity, achieving filtration efficiencies exceeding 99%.

Good Mechanical Strength: The needle-punched felt structure is dense and tough, resisting tearing and capable of withstanding high filtration airflow speeds and mechanical vibration.

High Cost-Effective: It offers balanced performance in terms of temperature resistance, wear resistance, and service life, with low maintenance costs.

Polyester needle felt filter bags are widely used in bag filters in industries such as cement, steel, power generation, chemicals, grain processing, and wood processing. They are particularly suitable for treating dust-laden gases with low acidity or alkalinity at ambient to moderate temperatures. For example, in cement plant raw material mills, packaging machines, and silo ceiling dust removal systems, they effectively capture fine dust, ensuring emissions meet standards.

To extend the service life of polyester needle felt filter bags, companies should select reputable suppliers when purchasing and using them, ensuring that the bag's weight, thickness, air permeability, and other parameters meet the requirements of the equipment and operating conditions. Furthermore, during operation, the filtration airflow speed should be properly controlled, and the cleaning system's operating status should be regularly inspected to prevent premature failure of the filter bags due to excessive dust accumulation or mechanical damage.

Polyester needle felt filter bags occupy an important position in the field of industrial dust removal due to their excellent filtering performance, stable mechanical strength and wide applicability. They are an ideal choice for enterprises to achieve efficient and environmentally friendly production.

latest News