Understanding Pulse Jet Pleated Filter Cartridges: Enhancing Industrial Filtration

Release time:

2025-06-17

Pulse jet pleated filter cartridges are an integral component in various industrial filtration systems, particularly in applications that require effective dust and particulate control. These filter cartridges are designed to enhance the performance of filtration systems, providing superior filtration efficiency while minimizing maintenance efforts. The design of a pulse jet pleated filter cartrid

Pulse jet pleated filter cartridges are an integral component in various industrial filtration systems, particularly in applications that require effective dust and particulate control. These filter cartridges are designed to enhance the performance of filtration systems, providing superior filtration efficiency while minimizing maintenance efforts.

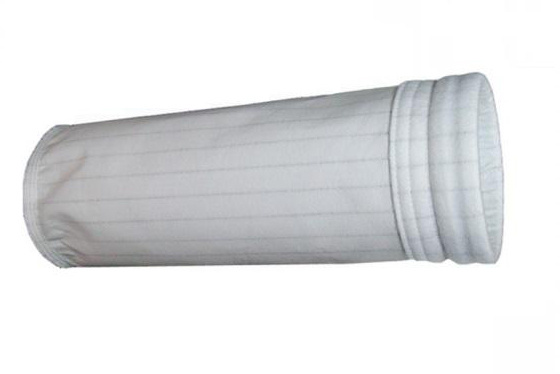

The design of a pulse jet pleated filter cartridge is characterized by its pleated structure, which maximizes the surface area available for filtration. This increased surface area allows for a greater volume of air to pass through the filter, effectively trapping dust and other airborne particulates. The pleating also facilitates a more compact design, allowing these cartridges to fit into smaller spaces without sacrificing performance.

One of the key advantages of pulse jet pleated filter cartridges is their compatibility with pulse jet cleaning systems. In industries where dust accumulation can impede efficiency, these cartridges can be cleaned using a burst of compressed air. This method of cleaning dislodges accumulated particles, allowing the filter to maintain its efficiency and prolonging its lifespan. The pulse jet cleaning process is effective in minimizing downtime, as it can be automated and performed while the system is still operational.

Moreover, these filter cartridges are often constructed from durable materials that can withstand harsh environmental conditions, making them suitable for a wide range of industrial applications. Industries such as pharmaceuticals, food processing, and manufacturing often utilize pulse jet pleated filter cartridges to ensure compliance with stringent air quality standards.

When selecting a pulse jet pleated filter cartridge for a specific application, it’s essential to consider factors such as the type of contaminants being filtered, the flow rate of the system, and the operating conditions. This information will help in choosing the right cartridge that meets the specific filtration needs of the operation.

In addition to their primary function of capturing particulates, pulse jet pleated filter cartridges can also contribute to overall energy efficiency. By maintaining optimal airflow and reducing resistance in the filtration system, these cartridges can lower energy consumption, resulting in cost savings for the facility.

In conclusion, pulse jet pleated filter cartridges play a vital role in enhancing industrial filtration systems. Their innovative design, combined with the ability to undergo pulse jet cleaning, makes them an ideal solution for maintaining air quality and operational efficiency in various industries. Understanding the benefits and proper application of these filter cartridges is crucial for any business aiming to improve their filtration processes and reduce maintenance costs.

The design of a pulse jet pleated filter cartridge is characterized by its pleated structure, which maximizes the surface area available for filtration. This increased surface area allows for a greater volume of air to pass through the filter, effectively trapping dust and other airborne particulates. The pleating also facilitates a more compact design, allowing these cartridges to fit into smaller spaces without sacrificing performance.

One of the key advantages of pulse jet pleated filter cartridges is their compatibility with pulse jet cleaning systems. In industries where dust accumulation can impede efficiency, these cartridges can be cleaned using a burst of compressed air. This method of cleaning dislodges accumulated particles, allowing the filter to maintain its efficiency and prolonging its lifespan. The pulse jet cleaning process is effective in minimizing downtime, as it can be automated and performed while the system is still operational.

Moreover, these filter cartridges are often constructed from durable materials that can withstand harsh environmental conditions, making them suitable for a wide range of industrial applications. Industries such as pharmaceuticals, food processing, and manufacturing often utilize pulse jet pleated filter cartridges to ensure compliance with stringent air quality standards.

When selecting a pulse jet pleated filter cartridge for a specific application, it’s essential to consider factors such as the type of contaminants being filtered, the flow rate of the system, and the operating conditions. This information will help in choosing the right cartridge that meets the specific filtration needs of the operation.

In addition to their primary function of capturing particulates, pulse jet pleated filter cartridges can also contribute to overall energy efficiency. By maintaining optimal airflow and reducing resistance in the filtration system, these cartridges can lower energy consumption, resulting in cost savings for the facility.

In conclusion, pulse jet pleated filter cartridges play a vital role in enhancing industrial filtration systems. Their innovative design, combined with the ability to undergo pulse jet cleaning, makes them an ideal solution for maintaining air quality and operational efficiency in various industries. Understanding the benefits and proper application of these filter cartridges is crucial for any business aiming to improve their filtration processes and reduce maintenance costs.

latest News